Introduction

On December 11, 2012, a 20-inch natural gas transmission pipeline ruptured near Sissonville, West Virginia, causing a catastrophic fire that destroyed homes, forced the closure of Interstate 77, and burned for over an hour. This event, known as the Sissonville Rupture, drew national attention and highlighted serious shortcomings in the pipeline operator's monitoring and emergency response protocols.

In this analysis, we will:

- Provide background and consequences of the incident

- Summarize key findings from the NTSB investigation

- Demonstrate, through simulation, how NIIMS (Networked Intelligent Integrated Monitoring System) could have drastically reduced the impact

Aftermath of the Sissonville pipeline rupture showing extensive fire damage

Background: The Sissonville Pipeline Rupture

The ruptured pipeline, operated by Columbia Gas Transmission, was installed in 1967 and had a Maximum Allowable Operating Pressure (MAOP) of 1,000 psig. At the time of rupture, it was operating at 929 psig. The failure occurred in a 20-inch-diameter pipe located approximately 106 feet west of Interstate 77.

Key Timeline:

- 12:41 p.m.: Pipeline ruptures, gas ignites almost immediately

- 12:55 p.m.: Fire reaches homes and burns five structures

- ~1:10 p.m.: I-77 is fully closed due to intense heat

- ~1:40 p.m.: Valves are manually closed to stop gas flow

Consequences

1. Life and Safety (LTI)

- Miraculously, there were no fatalities or serious injuries, but several residents narrowly escaped with only seconds to spare

- First responders were delayed due to confusion and heat hazards

2. Environmental Impact

- Acres of land were scorched

- Trees and soil near the rupture site were incinerated

- Air quality was impacted due to intense methane and combustion emissions

3. Financial Losses

- $5.5 million in property damage

- Millions in regulatory fines and litigation

- Business disruptions from highway closure and home loss

Damaged homes near the rupture site

Interstate 77 closed due to intense heat

NTSB Findings

The National Transportation Safety Board (NTSB) cited several systemic failures:

- Corrosion and wall thinning: Rupture was due to long-term degradation that went undetected

- No automatic shutoff valves: Manual shutoffs led to prolonged gas flow

- Lack of real-time anomaly detection: SCADA system did not recognize the rupture quickly

- Delayed notification and response: Operator was unaware until 12 minutes after ignition

NTSB concluded that the accident was entirely preventable with more robust monitoring and emergency procedures.

How NIIMS Could Have Changed the Outcome

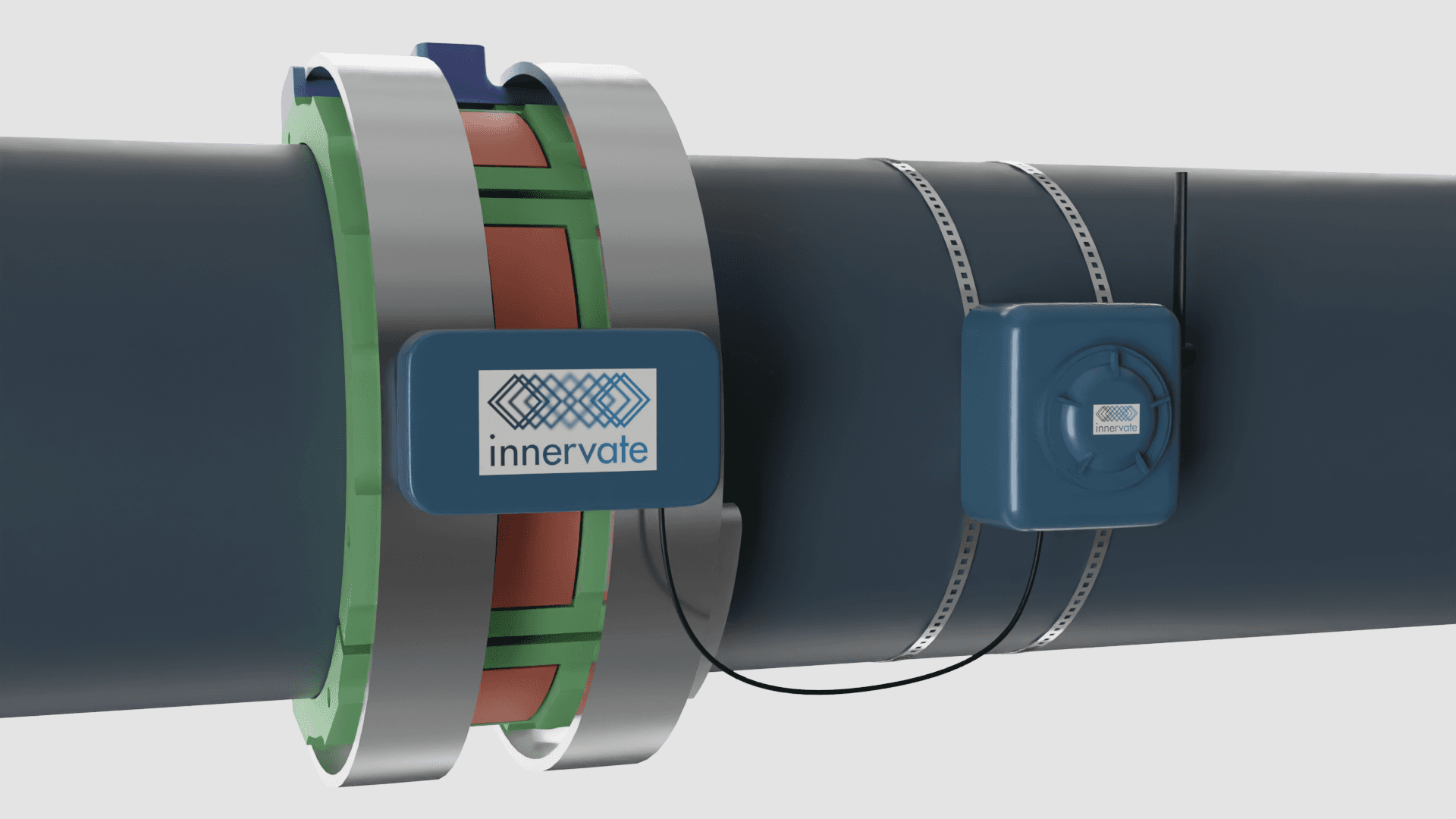

NIIMS (Networked Intelligent Integrated Monitoring System) is a non-intrusive, plug-and-play solution designed to rapidly improve pipeline safety. Unlike traditional SCADA systems, NIIMS can be deployed as a network of a handful of compact devices installed at fixed intervals along a pipeline. These devices are easy to install without interrupting operations and require minimal infrastructure.

Each NIIMS unit includes GPS synchronization, pressure and acoustic sensors, and real-time processing capabilities. Working together, the devices share data across the network, enabling not only the detection of anomalies but also precise localization of leaks or ruptures through spatial and temporal analysis.

NIIMS monitoring device with multi-parameter sensing capabilities

Using our enhanced simulation engine, we modeled the same rupture event assuming a deployed network of NIIMS sensors at 1-mile intervals.

Key Simulated Observations:

- Rupture Detection Time: <15 seconds

- Triggered Devices: NIIMS units at Mileposts 14, 15, and 16 all detected a 60%+ pressure drop within 30 seconds

- Escalation Triggered: Confidence scoring and voting logic initiated a "Possible Rupture" alert immediately

Response Advantage:

- Automated alert sent to control room within 20 seconds

- System-wide valve closure recommendation within 1 minute

- Potential to isolate the segment 30+ minutes earlier than in reality

Comparative Timeline

| Event | Actual Timeline | NIIMS Simulation |

|---|---|---|

| Rupture | 12:41 p.m. | 12:41 p.m. |

| Detection | 12:53 p.m. (12 min) | 12:41:15 p.m. (15 sec) |

| Alert to Control Room | 12:53 p.m. (via 911 call) | 12:41:20 p.m. (20 sec) |

| Valve Closure Decision | ~1:20 p.m. (39 min) | 12:42 p.m. (1 min) |

| Gas Flow Stopped | ~1:40 p.m. (59 min) | ~12:50 p.m. (9 min) |

Conclusion

The Sissonville tragedy serves as a cautionary tale—but also a powerful case study for the use of intelligent, distributed monitoring. NIIMS, by integrating real-time data fusion, confidence scoring, spatial clustering, and adaptive thresholds, demonstrates a transformative capability in pipeline safety.

If NIIMS had been deployed in 2012, it is highly likely the fire, property damage, and disruption could have been minimized—or even entirely avoided.

As the energy infrastructure modernizes, systems like NIIMS must be at the forefront—not just for compliance, but for safety, sustainability, and public trust.

Key Takeaways

- Early detection (within seconds, not minutes) is critical for preventing catastrophic outcomes

- Distributed sensor networks provide redundancy and spatial awareness that single-point monitoring cannot match

- Intelligent algorithms that can distinguish between normal operational changes and emergencies reduce false positives while ensuring critical events are flagged

- The ROI for advanced monitoring systems is clear when considering the potential costs of catastrophic failures

To learn more about NIIMS integration and simulations, contact our engineering team or request a technical demonstration.