Proprietary Technology

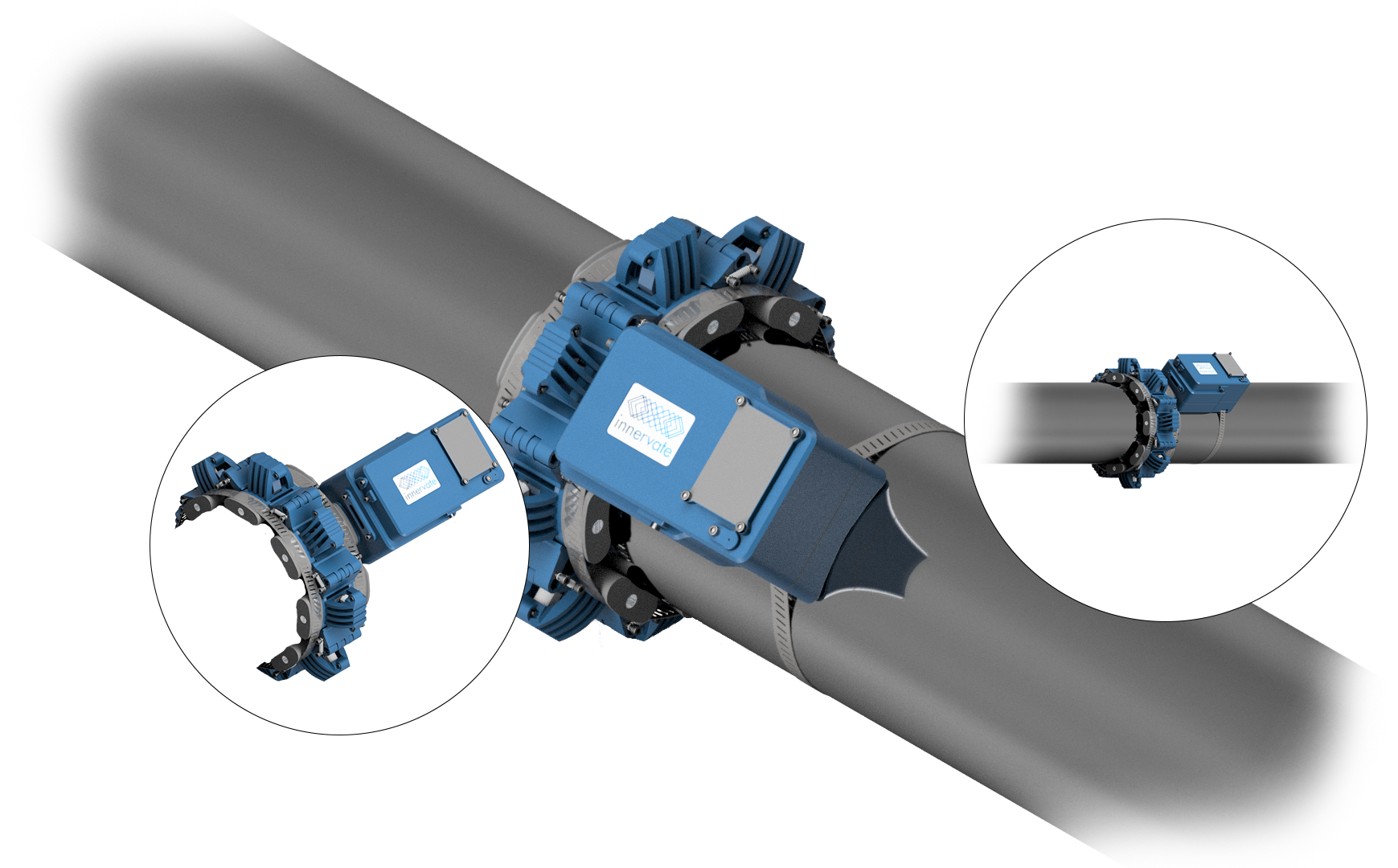

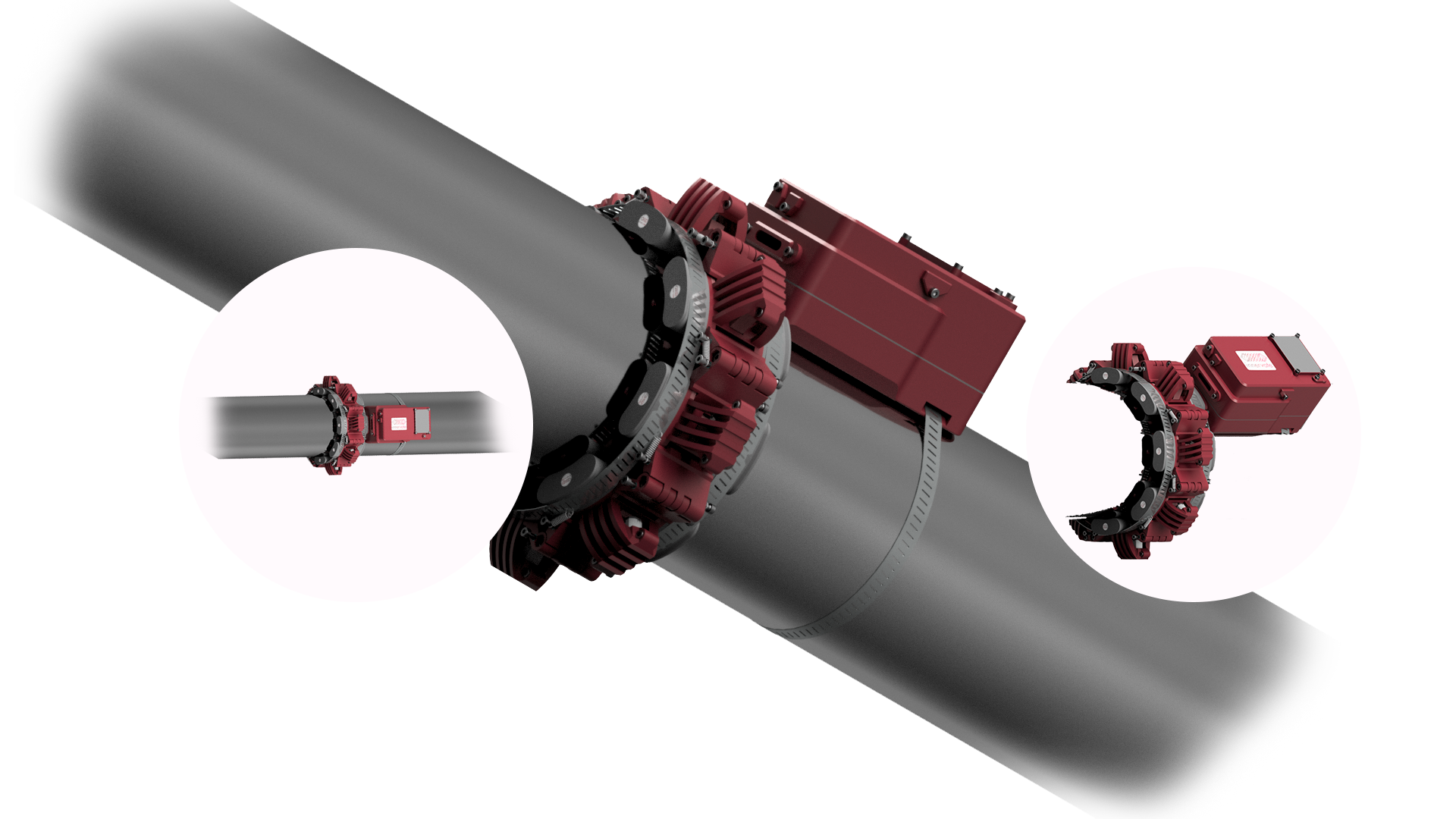

Dynamic Pipeline

|

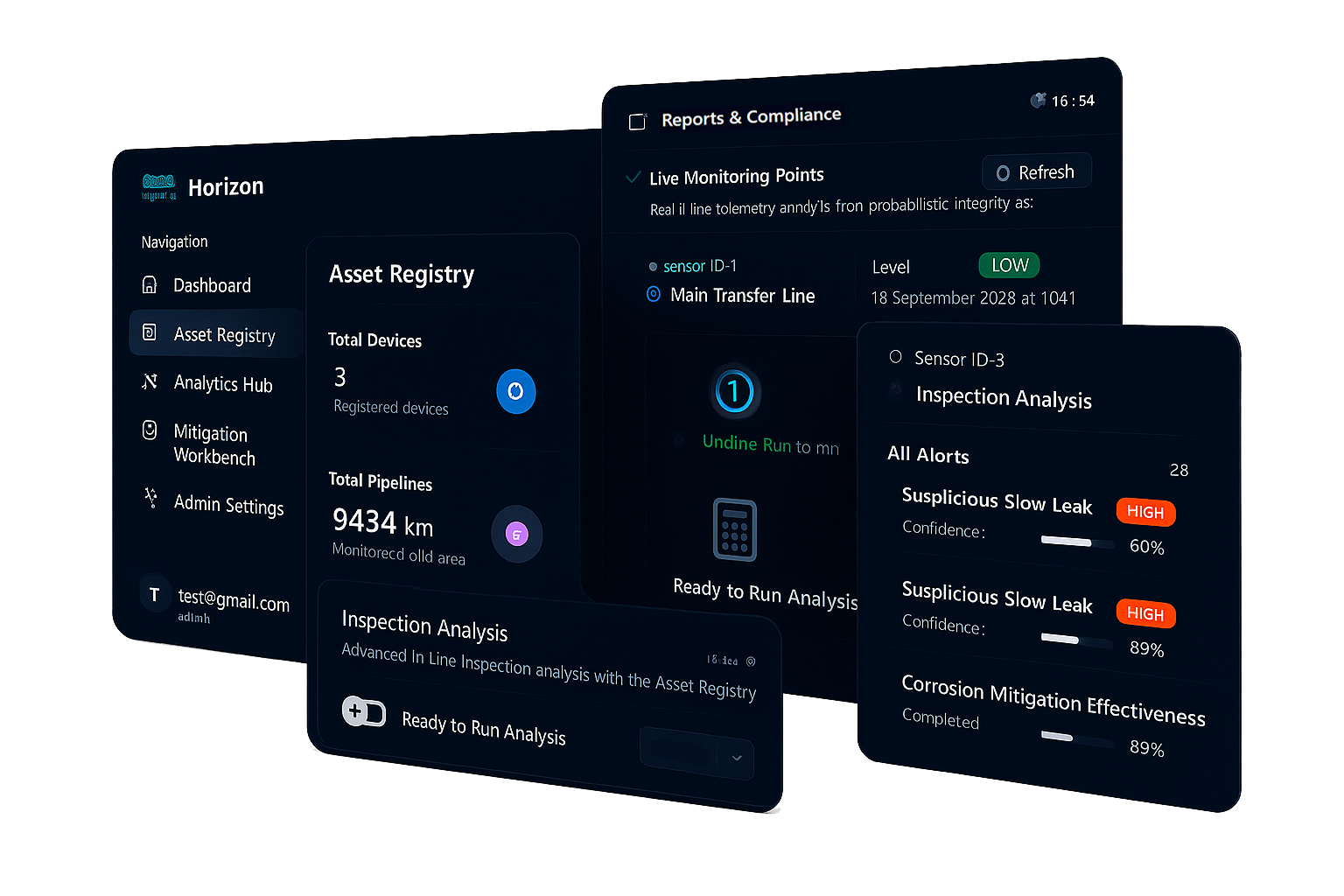

Our proprietary fusion of non-intrusive sensors and physics-informed machine learning transforms passive monitoring into continuous, adaptive intelligence.

Zero Mods

Non-Intrusive

Self-Learning

Adaptive

AI-Powered

Predictive

99.9%

Accurate

15 sec

Leak Detection

$5.5M+

Saved Per Incident

70%

Spill Reduction

Our Complete Product Suite

Explore our integrated platform of intelligent monitoring solutions

Innervate TechnologyFrequently Asked Questions

Everything you need to know about our technology solutions and services

Still have questions? Contact our team